BBS Wheel Refinishing – Before and After.

Before the restoration started. Note the curb rash.

We’ve been trying to source BBS RS 4×100 wheels and the only way we can get them efficiently is to do some BBS Wheel Refinishing. We purchased these 3 piece BBS RS wheels from our contact overseas and had them shipped directly to our WCR North shop. These BBS RS wheels came into the shop as 15”x6.5, 5×114.3 and looking pretty rough.

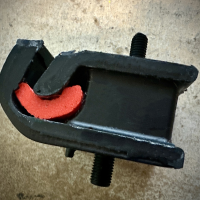

First, we start by stripping them down. For the lips, we started repairing the lips with some minor welding. The nex set was to machine and polish the lips to make them look perfect. Then, on the faces, we filled the 5×114 PCD lug holes with weld. We machined the welds flat and redrilled them to 4×100 PCD. We use a Jet Mill, index the wheels with a Accurite DRO and a coaxial indicator we we could drill a perfect PCD. Furthermore, we clean all 128 BBS wheel bolts, valve stems and tumbled them. We have a vibratory tumbler we use with walnut media for 24 hours.

After Refinishing

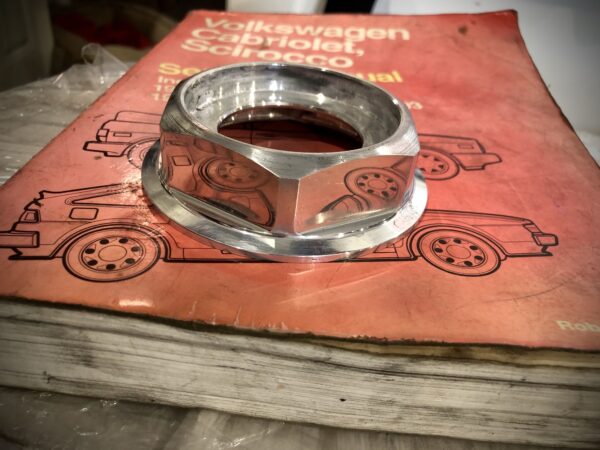

After this, we chemical strip, blast the centers, mask critical areas and powder coated with Porsche silver and clear coat powder. Disassembled the center caps, stripped, polished the nuts and found authentic red BBS caps from the UK. Then we reassemble, torque to spec and seal. Before the first wheel was finished we had them sold. In conclusion, these turned out amazing! We are always searching for a few more sets.

If you need a set or want yours refinished to your specifications, contact us at the West Coast Roccos North location.

- Before BBS RS Wheels

- Lip Repaired

- Fill and redrilled

- Back side

- Refinished nuts

- Finished Product BBS RS 15″

- BBS RS 15″

- Back side of finished product